In industrial automation, understanding the distinction between HMI (Human-Machine Interface) and SCADA (Supervisory Control and Data Acquisition) is crucial for building efficient, scalable, and secure control systems. Both technologies serve different purposes in the automation hierarchy, and knowing when and how to use each can significantly improve system performance and operator efficiency.

In this guide, we’ll break down how HMI and SCADA differ in industrial settings, including their core functions, architectures, components, integration protocols, and application scenarios. Whether you're a control system designer or an automation professional, this detailed comparison will help clarify which solution is right for your specific needs.

What Are HMI and SCADA? A Quick Definition

In industrial automation, it's vital to understand the distinction between HMI (Human-Machine Interface) and SCADA (Supervisory Control and Data Acquisition). These systems play distinct roles in managing industrial processes and equipment, yet they often work together to enhance control, monitoring, and efficiency across industries. Whether you're dealing with a single machine or a complex network of systems, selecting the right technology can significantly affect performance, scalability, and reliability.

What Is HMI in Automation?

HMI stands for Human-Machine Interface, and it refers to the digital interface that allows operators to interact with machines and control systems in real-time. Typically consisting of a touchscreen panel or a PC-based interface, an HMI provides visualizations of operating data—such as system pressures, valve states, temperatures, and alarms—allowing for intuitive, local control of machinery or equipment.

HMIs are primarily deployed in local control environments, where direct operator input is needed. They are commonly used in OEM (Original Equipment Manufacturer) machines, standalone workstations, and individual production cells. Operators use HMIs to start or stop machines, adjust setpoints, monitor process status, and respond to alerts. HMIs are ideal for isolated control tasks and small-scale operations where real-time machine feedback is crucial.

To streamline equipment operation with a tailored interface, explore our HMI and control panel solutions that are designed to integrate seamlessly with your automation strategy.

What Is SCADA in Industrial Operations?

SCADA, or Supervisory Control and Data Acquisition, is a broader, more centralized system designed to monitor and control multiple devices, processes, or even entire plants across large distances. It collects data from field devices such as PLCs (Programmable Logic Controllers) and RTUs (Remote Terminal Units), then transmits this data to a central SCADA server or operator terminal.

Unlike HMIs, SCADA systems are not limited to a single machine or area—they are capable of managing large, distributed operations, often across multiple locations. SCADA systems provide supervisory-level visibility and control, enabling operators to analyze trends, respond to alarms, generate compliance reports, and integrate with enterprise systems like ERP or MES platforms.

To support plant-wide automation or remote asset management, our SCADA development services deliver fully customized and secure architectures tailored to your industry's needs.

Core Components of HMI and SCADA Systems

Understanding the core components of HMI and SCADA systems helps you identify the right solution for your industrial automation needs. While both systems serve to improve control and monitoring, they are composed of different elements tailored to their specific functions. At Atlas OT, we build our automation architectures with the most reliable and compatible components, ensuring long-term performance and integration flexibility.

Key HMI Components

HMIs are designed to provide operators with direct interaction and visual feedback from machines or processes. Here are the primary components that make up a typical HMI system:

Graphical Displays

Touchscreen panels are the most common type of HMI display. They visually represent equipment status, process flow, alarms, and trends using intuitive graphics. These displays are often configured using HMI development software to create custom screens that align with the machine's operation. Icons, animations, and color-coded indicators help operators make informed decisions quickly.

Input Devices (Touchscreens, Keypads)

HMIs may include resistive or capacitive touchscreens, physical buttons, or membrane keypads depending on the environmental needs and user preferences. Touch interaction simplifies user experience and enables quick adjustments to machine settings. In some rugged industrial applications, tactile keypads are still used for added durability and precision. For advanced HMI setups with tailored interface layouts, explore our HMI and control panel services to discover how we deliver practical, operator-friendly solutions.

Key SCADA Components

SCADA systems are built for scale and centralized control. They consist of layered components that gather, transmit, process, and present real-time data from various field devices and systems.

RTUs and PLCs

Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs) are at the core of SCADA field operations. RTUs are often used in remote, harsh environments where they're tasked with collecting sensor data and executing control commands. PLCs, on the other hand, are more common in factory settings where deterministic control and high-speed logic execution are required.

SCADA Servers and Historian Databases

A centralized SCADA server aggregates data from field devices and enables visualization and supervisory control. Historian databases store long-term operational data, alarms, events, and performance metrics for analysis, reporting, and compliance purposes. These tools are critical for trend analysis, downtime reduction, and regulatory audits.

Networking Infrastructure

SCADA relies on robust and secure communication networks—wired (Ethernet, fiber optics) and wireless (radio, cellular)—to link all system components across sites. Protocol support like OPC UA or MQTT ensures data can be exchanged securely and reliably across multiple platforms. To guarantee efficient system communication, we offerseamless integration through PLC and DCS programming, aligning all components into a cohesive network.

Whether your focus is on localized control or wide-area supervision, understanding these core elements lays the groundwork for building efficient, resilient automation systems. Let our team at Atlas OT guide you through component selection and integration to match your operational goals.

Functional Differences Between HMI and SCADA

Although HMI and SCADA systems often work together in industrial environments, they serve distinct purposes. Understanding their functional differences helps automation professionals choose the right system for their operations—whether that’s local machine interaction or centralized supervisory control. At Atlas OT, we help clients match technology to application to improve performance and reduce downtime.

Scope and Scale

HMI: Localized Machine Interface

Human-Machine Interfaces are built for direct operator interaction with individual machines or small equipment clusters. These systems offer a limited scope of control and are generally installed right at the machine location. They are perfect for localized operations, such as packaging lines, bottling machines, and CNC stations. HMIs are typically not networked across an entire facility, though they can still share data with a central system if needed.

Ideal for one-on-one communication between a machine and an operator. Displays are simple and focused on immediate control, often including real-time feedback and alarm indicators. Easy to deploy and customize with minimal infrastructure.

SCADA: Plant-Wide or Multi-Site Supervision

SCADA systems, by contrast, are designed for wide-area visibility and control. They collect data from many field devices—often distributed across various buildings or even geographic locations—and transmit that information back to a central operator terminal or server.

SCADA allows centralized monitoring of thousands of data points from multiple sites. Operators can analyze trends, manage alarms, and remotely control processes. SCADA systems are perfect for complex operations like water treatment plants or oil & gas distribution networks.

You can learn more about our SCADA development capabilities if your needs involve large-scale, integrated control environments.

Although HMI and SCADA systems often work together in industrial environments, they serve distinct purposes. Understanding their functional differences helps automation professionals choose the right system for their operations—whether that’s local machine interaction or centralized supervisory control. At Atlas OT, we help clients match technology to application to improve performance and reduce downtime.

Scope and Scale

HMI: Localized Machine Interface

Human-Machine Interfaces are built for direct operator interaction with individual machines or small equipment clusters. These systems offer a limited scope of control and are generally installed right at the machine location. They are perfect for localized operations, such as packaging lines, bottling machines, and CNC stations. HMIs are typically not networked across an entire facility, though they can still share data with a central system if needed.

Ideal for one-on-one communication between a machine and an operator. Displays are simple and focused on immediate control, often including real-time feedback and alarm indicators. Easy to deploy and customize with minimal infrastructure.

SCADA: Plant-Wide or Multi-Site Supervision

SCADA systems, by contrast, are designed for wide-area visibility and control. They collect data from many field devices—often distributed across various buildings or even geographic locations—and transmit that information back to a central operator terminal or server.

SCADA allows centralized monitoring of thousands of data points from multiple sites. Operators can analyze trends, manage alarms, and remotely control processes. SCADA systems are perfect for complex operations like water treatment plants or oil & gas distribution networks.

You can learn more about our SCADA development capabilities if your needs involve large-scale, integrated control environments.

Data Logging and Analysis

One of the primary differences between the two lies in data retention and analysis. While HMI systems may log basic alarms or offer short-term trend viewing, SCADA platforms are equipped with historian databases for long-term storage and analytics.

SCADA systems support detailed reporting and regulatory compliance documentation. This makes SCADA crucial in industries like utilities and energy, where tracking trends over time is essential for efficiency and accountability.

Control Capabilities and User Interaction

HMIs focus on real-time interaction, letting operators immediately adjust settings or respond to machine feedback. SCADA, however, provides supervisory control, enabling high-level decision-making with support from historical data and alarms.

Both systems are vital in their roles. When combined, they provide a layered approach—HMI at the local level and SCADA at the supervisory level. For a more robust and secure control infrastructure, we recommend a hybrid deployment, supported by our custom PLC and DCS programming services.

System Architecture Comparison

When comparing HMI and SCADA systems, one of the most fundamental differences lies in their architectural design. How each system is built—from device connections to server infrastructure—defines its capabilities, scalability, and application in industrial environments. At Atlas OT, we design architecture that’s not just functional but built for future growth and seamless system integration.

Typical HMI Architecture (Single-Device Interaction)

HMI systems are usually self-contained, with limited connectivity beyond the machine they control. This makes them easier to install and operate but also limits their scalability.

HMI devices typically connect directly to a single PLC or controller using simple industrial protocols like Modbus RTU or CAN bus. The architecture consists of a touchscreen panel or display, controller interface, and local sensors/actuators. Data logging, if present, is often stored locally on the device or a USB, without centralized analysis tools.

This localized approach works well for operations such as OEM machinery, bottling lines, or localized HVAC systems, where on-site control is sufficient. For user-friendly interface designs with robust connectivity, explore our HMI and control panel services.

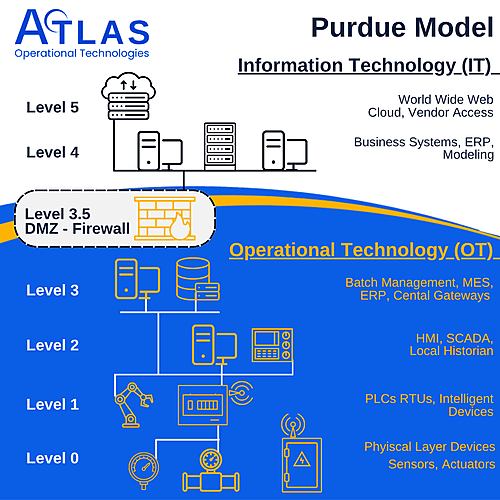

SCADA Architecture (Multi-Tier Distributed Control)

Unlike HMI systems, SCADA is built on a tiered and distributed architecture that supports large-scale industrial supervision.

Field Layer: RTUs/PLCs

●The bottom layer consists of Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs) that gather sensor data and perform logic-based control.

●These devices often span large areas—think pumping stations, substations, or process facilities.

Control Layer: SCADA Software

●Field devices send real-time data to SCADA servers via protocols like OPC UA, DNP3, or MQTT.

●The SCADA software aggregates, visualizes, and logs this data for operator use.

Enterprise Layer: ERP/Cloud/MES Integration

●At the top tier, SCADA systems interface with enterprise tools like ERP (Enterprise Resource Planning), MES (Manufacturing Execution Systems), and cloud platforms.

●This enables predictive maintenance, production analytics, and supply chain synchronization.

We offerseamless integration through PLC and DCS programming to align your field devices with your enterprise systems and ensure smooth communication across layers.

Why Architecture Matters

Choosing the right architecture affects everything from system response times to cybersecurity and maintenance costs. If you're running a single machine, a standalone HMI may be enough. But if you're supervising multiple sites or need centralized control, SCADA's architecture offers unmatched visibility and command.

Our team at Atlas OT specializes in designing both HMI and SCADA architectures tailored to your facility’s needs, ensuring your investment supports long-term scalability and operator efficiency.

When to Use HMI vs. SCADA

Choosing between HMI and SCADA isn’t always about picking one over the other—it’s about selecting the right tool for the job. Each system offers unique strengths depending on the scale, complexity, and interactivity of your operations. At Atlas OT, we help clients make informed decisions by evaluating specific use cases, environments, and operational goals. Here's how to determine which system fits your needs best.

Best Use Cases for HMI

HMI systems shine in environments where operators interact directly with machinery or production equipment on the shop floor. These interfaces offer visual feedback and real-time controls at the local level.

OEMs and Packaging Lines

HMI panels are ideal for Original Equipment Manufacturers (OEMs) building standalone equipment like CNC machines, robotic arms, or injection molders. Packaging lines often rely on HMI touchscreens to monitor status, adjust speeds, and troubleshoot jams. In these applications, centralized monitoring is less critical than local responsiveness and intuitive control.

Local Machine Operations

HMIs excel in facilities where machine operators need fast access to operational data like temperature, motor status, or material flow. Because they're located right on the machine, they provide immediate insight without the need for networked infrastructure. If your focus is on local process control with minimal system complexity, we recommend checking out our HMI and control panel services to see how we design interfaces for both ease of use and durability.

Best Use Cases for SCADA

SCADA systems are essential for operations that span multiple machines, systems, or even geographic regions. They allow for centralized supervision, historical analysis, and intelligent alerts.

Remote Pumping Stations

Water and wastewater utilities often have dozens of remote sites. SCADA systems let you monitor tank levels, flow rates, and chemical dosing from a central control room. Real-time alerts and trend tracking enable proactive maintenance and compliance with water quality standards.

Industrial Utilities or Energy Grids

SCADA plays a critical role in electrical substations, gas distribution networks, and power generation facilities. Operators need to visualize load distribution, detect faults, and make system-wide decisions rapidly. For these multi-layered environments, learn more about our SCADA development capabilities to see how we build scalable control systems for 24/7 uptime.

Hybrid Deployment Scenarios

In reality, many facilities benefit from a combination of both HMI and SCADA. For example:

- A manufacturing facility could deploy SCADA for its production line analytics and environmental controls, while each piece of equipment still runs its own local HMI.

These hybrid deployments offer the best of both worlds—localized control with global visibility. Atlas OT specializes in designing integrated architectures that combine the flexibility of HMI with the power of SCADA, all through seamless PLC and DCS integration.

Protocols, Compatibility, and Integration

When evaluating SCADA and HMI systems, protocol compatibility and integration flexibility are key to ensuring seamless data communication across all layers of an automation system. From field-level devices to enterprise systems, the right protocols make it possible for HMIs and SCADA to work reliably in real-time. At Atlas OT, we focus on designing systems that are protocol-agnostic, interoperable, and ready for future scaling.

HMI Protocols

Human-Machine Interfaces typically communicate with PLCs, drives, and sensors using well-established field-level protocols. These protocols are engineered for speed, simplicity, and reliability over short distances.

Common HMI Protocols:

●Modbus RTU: A serial communication protocol still widely used for basic equipment. It’s simple, reliable, and perfect for legacy systems.

●CAN bus: Popular in automotive and machine control environments, CAN is known for its fault tolerance and rapid communication.

●Ethernet/IP: A higher-speed industrial Ethernet protocol that provides better bandwidth, making it ideal for modern HMI-to-controller interfaces.

These protocols allow HMIs to deliver real-time data visualization, alarms, and diagnostics directly from the machine level. Whether your system uses legacy Modbus or modern Ethernet-based communication, we tailor HMI and control panel solutions to support your preferred protocol stack.

SCADA Protocols

SCADA systems, by contrast, must integrate with a much broader range of devices over long distances. Therefore, their protocols focus not only on communication speed but also on security, scalability, and structured data handling.

Common SCADA Protocols:

●OPC UA (Open Platform Communications Unified Architecture): A modern, platform-independent protocol designed for secure data exchange across diverse systems.

●MQTT (Message Queuing Telemetry Transport): A lightweight publish/subscribe protocol ideal for remote telemetry and cloud-connected SCADA applications.

●DNP3 (Distributed Network Protocol): Frequently used in utilities like water and energy for reliable and time-stamped data transmission.

●BACnet: Designed specifically for building automation and HVAC systems, enabling control over lighting, HVAC, and energy systems.

These protocols enable SCADA software to monitor, control, and log data across an entire facility or even multiple sites. If you're planning to scale your operations across locations, explore our SCADA development capabilities for expert support in protocol configuration and integration.

How HMI and SCADA Interoperate via PLCs

PLCs (Programmable Logic Controllers) act as the bridge between HMI and SCADA systems. Both platforms often pull data from the same PLC, but use it differently:

●HMIs use PLC data for local control—turning motors on/off, adjusting parameters, or clearing alarms.

●SCADA systems use the same data for supervisory control—creating trends, generating reports, and making centralized decisions.

To achieve a seamless architecture, your PLC must support dual communication channels (for example, Modbus for HMI and OPC UA for SCADA). Our team ensures seamless integration through PLC and DCS programming, allowing both HMI and SCADA to operate harmoniously without data conflict.

Industry Use Cases by Sector

Understanding the real-world applications of HMI and SCADA systems helps clarify why both technologies remain vital in industrial automation. From water utilities to food processing and energy management, the needs of each industry vary—and so does the role of HMI and SCADA. At Atlas OT, we specialize in building tailored automation systems that align with sector-specific requirements, operational environments, and compliance needs.

Water/Wastewater Utilities

Water and wastewater operations demand continuous monitoring, remote control, and strict compliance with environmental standards. SCADA is the clear choice here. SCADA systems manage distributed assets such as pumping stations, reservoirs, and treatment plants, allowing central operators to monitor flow, tank levels, and chemical dosing. Real-time alerts enable quick response to pressure drops, overflows, or equipment failures. Historical data from SCADA is crucial for regulatory reporting and trend analysis.

In these projects, HMI panels are still used locally for maintenance teams to troubleshoot on-site equipment. For multi-site water systems, we recommend learning more about our SCADA development capabilities, where we design robust architectures suited to long-term, 24/7 operations.

Oil & Gas SCADA Networks

Oil and gas operations, particularly upstream and midstream, require highly secure, scalable, and fault-tolerant SCADA systems. In pipeline networks, SCADA oversees pressure levels, leak detection, and flow control across vast distances. Remote terminal units (RTUs) feed live data back to the control center using protocols like DNP3 or MQTT. Real-time monitoring helps prevent critical failures and supports asset management.

On drilling rigs or local separators, HMI systems provide immediate feedback to field technicians. Whether you're managing offshore platforms or land-based fields, Atlas OT provides seamless PLC integration to unify field-level controls with centralized SCADA dashboards.

Food & Beverage Packaging Lines

In food and beverage, the focus is on speed, hygiene, and traceability. Here, HMI systems take the spotlight.

●Operators use HMIs on each packaging machine to control conveyor speeds, product counts, and error messages.

●Quick-change interfaces enable recipe switching with minimal downtime.

●Touchscreen interfaces streamline interaction, even with gloved hands.

SCADA may still be present at the supervisory level to monitor overall production KPIs, track OEE (Overall Equipment Effectiveness), and log batch data for audits. For hygienic and ergonomic interface design,explore our HMI and control panel services.

Building Automation and HVAC

In commercial and institutional buildings, HMI and SCADA combine to manage energy use, lighting, and indoor climate.

- HMIs installed at mechanical rooms or air handling units give technicians a hands-on way to adjust settings and perform diagnostics.

Building managers benefit from data visualization and remote alerts, optimizing comfort while reducing energy consumption. Our team ensuresfull BACnet and HVAC system integration, giving you full visibility and control across your facility.

Security and Compliance Considerations

In today’s connected industrial environments, security is not optional—it’s foundational. Both HMI and SCADA systems can become entry points for cyber threats if not designed and maintained properly. As a company committed to building resilient control systems, Atlas OT prioritizes security and regulatory compliance from the design phase to deployment. Whether you're protecting a single machine interface or an entire plant-wide SCADA network, here’s what you need to know.

HMI Security Best Practices

HMI systems often sit on the front lines—directly accessible to operators on the shop floor. While they may seem isolated, they’re often networked with PLCs, drives, and supervisory systems. This makes them a potential vulnerability if not properly secured.

Key HMI security practices include:

- Physical safeguards (like lockable enclosures) to prevent tampering with touchscreen panels.

- Disabling unused ports and services, such as USB access or remote desktop features.

- Firmware and software patch management to ensure all interface devices are up to date.

Additionally, we emphasize secure programming through ourPLC and DCS integration services, where every control logic is validated for safe operation, even if an HMI is compromised.

SCADA-Specific Threats

SCADA systems are particularly vulnerable due to their broad network exposure and remote access features. Because SCADA connects multiple systems across wide areas, it becomes a high-value target for cybercriminals and nation-state actors.

Common SCADA threats include:

- Protocol hijacking, especially in legacy systems that still use Modbus or early DNP3 without encryption.

- Insider threats, where unauthorized users with access credentials make malicious or erroneous changes.

To mitigate these risks, SCADA deployments should include:

- Role-based authentication with multi-factor verification for critical changes.

- Audit logging and anomaly detection using intrusion detection systems or AI-based monitoring.

Atlas OT builds secure SCADA architectures from the ground up, incorporating modern protocols like OPC UA and MQTT that support encryption and fine-grained access control.

Compliance with NIST, IEC 62443, and OOOOabc

Compliance isn't just a checklist—it's a commitment to safe, sustainable, and industry-aligned operations. Atlas OT supports clients with security consulting and design that align with leading standards, including:

- IEC 62443: The international benchmark for securing Industrial Automation and Control Systems (IACS), detailing roles, zones, conduits, and security levels.

- OOOOabc (Quad-O ABC): This EPA-driven compliance standard is crucial for emissions monitoring and control, especially in oil & gas and chemical sectors.

For clients navigating these complex frameworks, we ensure system security through OOOOabc compliance consulting and full-spectrum engineering services—see how we can support your compliance journey here.

Future of HMI and SCADA: Trends for 2025

The landscape of industrial automation is evolving rapidly. As digital transformation takes deeper root in manufacturing, utilities, and critical infrastructure, HMI and SCADA systems are being reimagined for greater intelligence, mobility, and connectivity. At Atlas OT, we’re at the forefront of these changes—helping our clients future-proof their automation investments with scalable, secure, and innovative solutions.

AI/ML Integration in SCADA for Anomaly Detection

One of the most transformative developments is the integration of Artificial Intelligence (AI) and Machine Learning (ML) into SCADA systems. While traditional SCADA systems offer monitoring and control, AI-enhanced SCADA brings predictive insights and automated decision support.

Key benefits include:

- Predictive analytics: AI can forecast equipment failure or production inefficiencies before they become critical issues.

- Process optimization: Adaptive learning models can fine-tune setpoints and reduce energy consumption without human intervention.

These intelligent layers are particularly valuable in large-scale operations such as water distribution, energy grids, and manufacturing facilities. If you're exploring SCADA upgrades, learn more about our SCADA development capabilities to see how Atlas OT can incorporate AI-ready architecture into your system.

Cloud SCADA and Edge HMI Deployments

The move toward decentralized, cloud-enabled systems is also accelerating. Instead of housing all SCADA data on local servers, many organizations are adopting Cloud SCADA platforms that offer remote access, scalability, and advanced analytics.

Benefits of Cloud SCADA include:

- Lower infrastructure costs

- Real-time access from anywhere with proper security

Meanwhile, Edge HMI is growing in importance for localized decision-making. These next-generation HMIs process data on-site and only transmit essential information to the cloud, ensuring faster response times and bandwidth efficiency.

Hybrid deployments—where edge HMI panels work alongside cloud-hosted SCADA—are becoming the norm. This approach combines the best of both worlds: real-time responsiveness with centralized intelligence.

Mobile Access and Augmented Reality Interfaces

Mobility and visualization are key trends shaping the future of operator interfaces. Modern SCADA and HMI systems now offer:

- Augmented Reality (AR) overlays that guide technicians during maintenance or inspections by showing live data on machine components.

- Web-based HMIs that can be securely accessed from any browser without the need for proprietary software.

These technologies significantly boost operator efficiency, reduce response time to faults, and support remote collaboration.

At Atlas OT, we design systems that are not only functional today but ready for tomorrow’s demands. Whether you're planning for mobile access, edge deployment, or AI-enhanced monitoring, we help you build smart automation ecosystems that grow with your business.

Final Takeaways: Which System Do You Need?

Choosing between HMI and SCADA—or determining how both can work together—isn’t always straightforward. At Atlas OT, we help industrial businesses evaluate their operational goals, technical needs, and long-term scalability to make the best decision for their control system architecture. Let’s break it down.

Questions to Ask Before You Choose

- Do you need local control, remote monitoring, or both? HMI is best suited for local operator control. SCADA allows enterprise-wide visibility and oversight.

- What level of data logging and analysis is required? If you need detailed historical records and predictive insights, SCADA provides superior logging and trend capabilities.

- Do you need real-time alerts and system-wide coordination? SCADA is designed for centralized command with distributed data collection.

- What are your compliance and cybersecurity obligations? For industries bound by EPA or cybersecurity standards, robust SCADA systems aligned with OOOOabc compliance may be required.

Answering these questions helps you define whether a standalone HMI, a full SCADA deployment, or a hybrid system is the right fit.

Combined Systems for Maximum Efficiency

Here’s how combining them adds value:

- Supervisors and engineers monitor performance and respond to issues using SCADA dashboards.

- Data flows from HMIs and PLCs to the SCADA historian for analytics, compliance, and optimization.

- The system scales with your needs—from a single site to a global network.

We often recommend hybrid setups in industries like water treatment, oil & gas, and advanced manufacturing, where both local control and broad oversight are essential.

How Atlas OT Delivers Customized SCADA/HMI Architecture

At Atlas OT, we don’t believe in one-size-fits-all automation. Every plant, facility, or system has its own set of requirements, from compliance and user experience to data visibility and scalability.

Here’s how we help you succeed:

- Start your next automation project with expert EI&C drafting that captures every detail of your process —learn more about our EI&C drafting services.

- We develop robust SCADA solutions tailored to your environment, protocols, and monitoring needs —explore our SCADA development capabilities.

- Our custom-built HMIs and control panels ensure safe, efficient operator interaction —see our HMI and panel services.

- We offer seamless integration through PLC and DCS programming, making sure your field equipment, interfaces, and supervisory systems speak the same language —discover our integration expertise.

- Need support with emission monitoring or regulatory design? We ensure system security through OOOOabc compliance consulting —view our compliance services.

By aligning design, hardware, software, and compliance, we create integrated control systems that deliver real-world value and peace of mind.